Avocado Ripening: the problem

A common way to determine the ripeness of a batch of Avocado’s is to take a product sample and execute a manual penetrometer test. These tests are destructive by nature, and require a lot of time and products.

The Ripening Master will enter the Ripening Room, take the sample out and register the Firmness of each Avocado. Based on the average Firmness and the spread between pallets, it could be decided to split the batch as to divide pallets over Ripening Rooms.

A ripe sequence typically lasts 3-5 days and while the first day the room will stay closed due to the exogenous Ethylene influx, the other days products might be tested. It is clear that in a situation with 80 Ripening Rooms, this requires a lot of effort and money in terms of time of specialized personnel and wasted products.

Avocado Ripening: the calculation

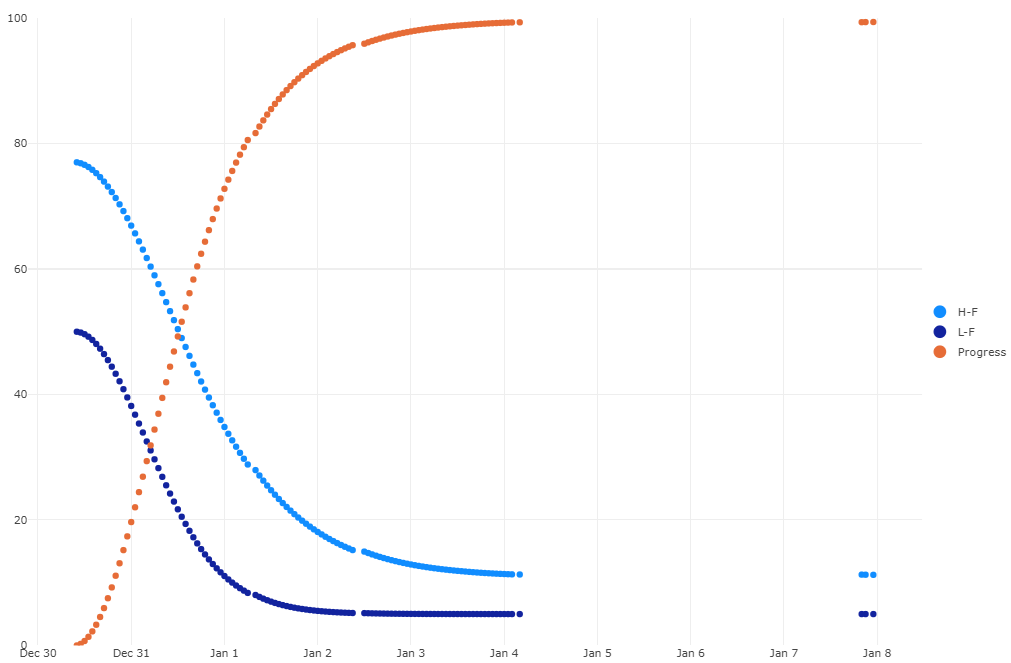

NovaSets developed a solution that calculates the Lower and Upper bands of the Firmness of the batch based on air samples that are analyzed by Gas Analyzers at regular intervals. The Lower and Upper bands represent the prediction interval of 80%, so if a Ripening Master takes a manual Penetrometer sample, 80% of the variation in that sample will fall between these band. The Firmness is calculated with help of physiological formulas that are based on the pathways know to happen within the fruit. Derived from this, we calculate the %-Complete of the batch.

Although the models have been created for Avocado, it is believed that the majority of the formulas will hold for other types of fruit as well.

Avocado Ripening: Connecting to the Control System

With the current setup in place, the next step will be to add the following elements to the system:

- – Reading in the ‘Planned Finish Time’

- – Reading in the “Required Ripeness Stage’

- – Calculating Temperature Adjustments to meet the ‘Planned Finish Time’. These temperatures should not be below and above natural Ripening Temperatures.

- – Generating Alarms when ‘Planned Finish Time’ is deemed unrealistic, that is when the temperature adjustments to meet the ‘Planned Finish Time’ exceed the ‘Natural Ripening Temperatures’.

- – Sending signals over Modbus to adjust the temperature settings

With these added elements, we are able to create a fully automatic ripening system.